Under-Floor Trunking in Raised Floors: Challenges & Best Practices

In UAE construction and engineering projects, raised access flooring and underfloor trunking systems have become an important part of modern infrastructure. In commercial buildings, government offices, hospitals, and data centers, they provide secure distribution of power, data, and ventilation under the finish coating. Thanks to the hidden placement of engineering communications, such systems improve the aesthetics of rooms, increase energy efficiency and allow flexible adaptation of workspaces to future requirements.

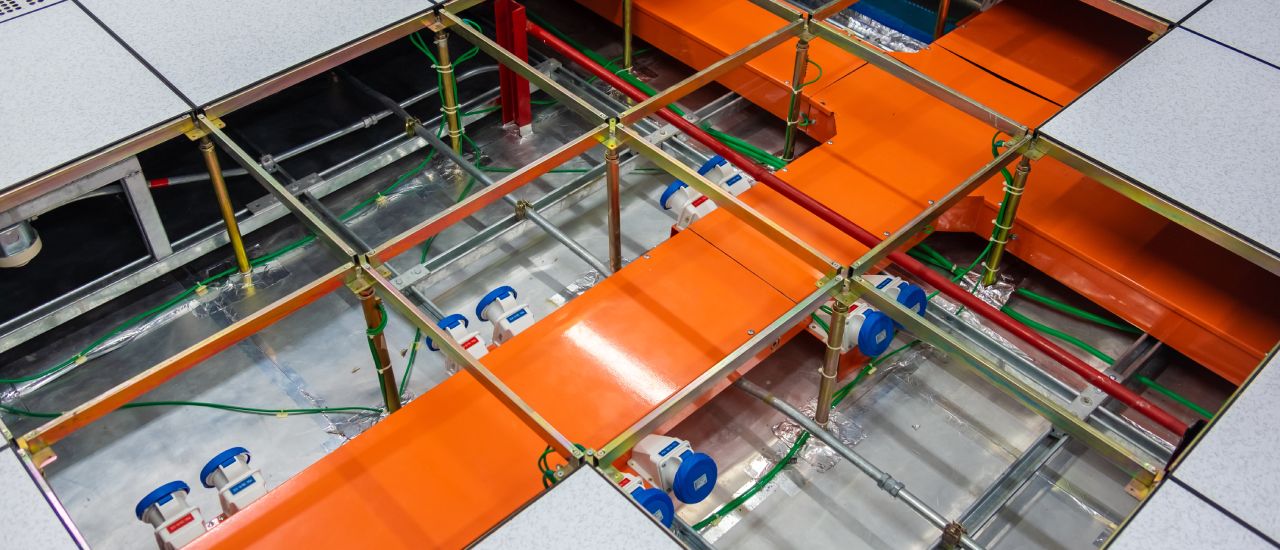

Construction and materials of underground cable control systems

The underfloor trunking system in typical UAE projects consists of galvanized steel or aluminum conforming to BS EN 10346 standard, with an anti-corrosion coating designed for the hot and humid climate of the region. The channel sizes range from 50x50 mm to 150 x 150 mm, and the depth of the concrete screed must exceed the height of the duct by at least 25 mm for reliable protection and stability.

Low profile raised floors with heights from 38 mm to 152 mm are more often used in administrative buildings and training centers, providing convenient placement of cables and communication networks without loss of ceiling height. Aluminum trunking systems that do not create magnetic distortion are used for facilities that require protection from electromagnetic interference, such as medical facilities or laboratories. Multi-section channels (single, double and triple) are widely used in data centers and banks to isolate power and low-current networks, which increases reliability and operational safety.

The main engineering challenges in operation

One of the key tasks in the design of raised access flooring in the UAE is to ensure the stability of the system to loads and climatic influences. The temperature and humidity in the rooms can vary, which, if the materials are not properly selected, leads to deformation of the panels and weakening of the footrests. The height of the racks is selected based on the volume of engineering networks and usually ranges from 610 mm to 1219 mm.

Subfloor stability control remains a serious problem. If the base is uneven, gaps appear between the plates, the bearing capacity decreases and the risk of loosening of the coating increases. Therefore, even at the design stage, it is necessary to perform precise alignment of the concrete slab and provide for the reinforcement of the screed at the points of passage of the cable channels.

It is also important to consider the density of cable routes. In rooms with a high concentration of server equipment or security systems, cables should be placed in underfloor cable trays, separated by connection type, to prevent overheating and electromagnetic interference.

Energy efficiency and regulatory compliance

With UAE's commitment to sustainable development (UAE Vision 2030), special attention is being paid to energy efficiency of engineering solutions. Underfloor air distribution (UFAD) systems can improve the circulation of cooled air and reduce the burden on air conditioning.

Efficiency is achieved through the use of perforated panels with a throughput of 22-35%, and panels with increased permeability of up to 66% are used for rooms with a dense IT load.

According to the requirements of BS EN 50085-1 / 50085-2-2 and IEC 61537, all elements of cable ducts must be load-resistant and comply with fire safety standards. The projects being coordinated in the municipalities of Dubai, Abu Dhabi and Sharjah also take into account the requirements of DEWA, SEWA and ADDC regarding electrical safety and energy efficiency. Fire-rated trunking systems and heat-resistant partitions are used to increase protection.

In addition, the use of busbar systems instead of a traditional cable connection ensures modularity and ease of rebuilding electrical circuits without power outage. This is especially important for buildings with round-the-clock operation, such as data centers, airports, and medical complexes.

Maintenance, prevention and prolongation of service life

Regular maintenance is an important element of the long-term reliability of underfloor cable trunking and raised access flooring systems. It is recommended to inspect the support posts and panels at least twice a year, paying attention to the alignment, fixation and condition of the underlying layer. Damaged elements can be replaced without dismantling the entire structure, which is especially convenient when operating large commercial premises.

It is equally important to keep the underground space clean. Dust and building particles accumulating in the underfloor void zone reduce cooling efficiency and accelerate the wear of cable sheaths. The use of sealed grommets and proper cable distribution help reduce the risk of overheating.

To increase durability, it is recommended to use panels made of durable materials such as steel, aluminum or calcium sulfate with anti-corrosion treatment. Such panels can withstand static loads of up to 25,000 pounds, and the service life with regular maintenance exceeds 25 years, while the support posts can last over 50 years.

Best practices for projects in the UAE

- Climate-specific planning. Use materials that are resistant to high temperature and humidity, as well as provide for microclimate control in the underground space.

- Design flexibility. For projects with frequent layout changes, use low profile raised floors with modular panels that provide easy access to communications.

- Installation quality control. During the installation phase, pay special attention to aligning the substrate and fixing the racks to prevent the panels from loosening.

- Regular diagnostics. Carry out routine inspections of the condition of cable ducts, supports and connections to prevent overloads and local damage.

With proper design, certified materials, and system maintenance, underfloor trunking becomes a reliable part of the UAE's building engineering infrastructure. Such solutions not only meet high safety requirements, but also support sustainable development by reducing energy consumption and increasing the adaptability of commercial and public spaces for decades.