Beyond Steel: How to Identify a Reliable Slotted Channel Manufacturer

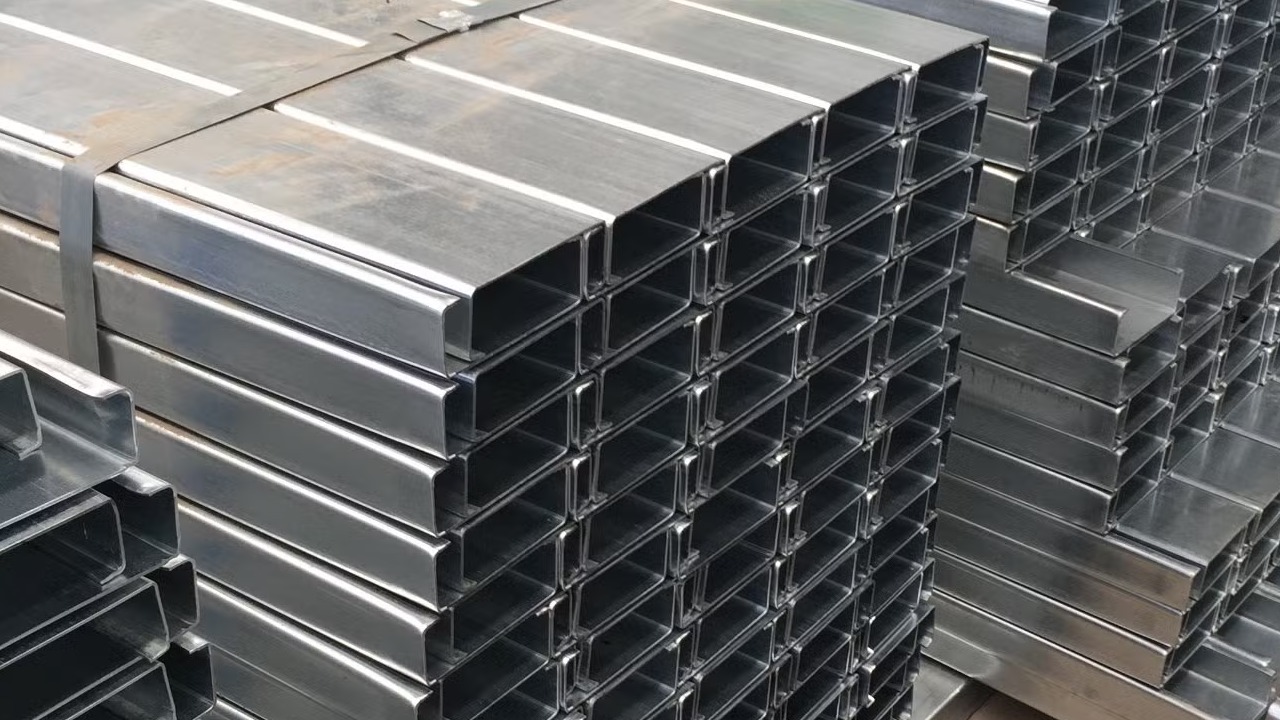

Slotted channels play a pivotal role in modern construction, electrical, HVAC, and industrial support systems. While often perceived as a commodity product, the performance, safety, and longevity of slotted channel installations are directly influenced by the slotted channel manufacturer behind them. This article examines the critical technical, operational, and commercial factors that must be evaluated when selecting a slotted channel manufacturer, supported by industry benchmarks, quality standards, and infrastructure analytics.

Why the Manufacturer Matters More Than the Product

In infrastructure engineering, system reliability is rarely compromised by design alone—it is more often undermined by manufacturing inconsistencies. Slotted channels, also referred to as strut channels, serve as structural support frameworks for cable trays, pipework, HVAC systems, and solar installations. According to construction material performance studies, over 60% of premature support-system failures are attributed to substandard materials or poor manufacturing controls. Choosing the right slotted channel manufacturer is therefore not a procurement decision; it is a strategic risk-management exercise.

Material Quality and Metallurgical Integrity

Material specification is the first and most important factor to take into account when assessing a slotted channel manufacturer. Mild steel, pre-galvanized steel, hot-dip galvanised steel, or stainless steel (Grades 304/316), each appropriate for particular environmental conditions, are commonly used to make high-quality slotted channels.

According to industry data, irregular galvanisation or incorrectly specified steel thickness can lower load-bearing capability by 20–35%. A reputable slotted channel manufacturer guarantees consistent mechanical strength and corrosion resistance by adhering to international material standards like ASTM A653, EN 10346, or ISO 1461. Compared to long-term installations, manufacturers with internal material testing and traceability procedures offer noticeably greater reliability.

Dimensional Accuracy and Load Performance

In support systems, precision cannot be compromised. Compatibility with fasteners, brackets, and accessories can be jeopardized by even small variations in slot spacing or channel depth. Dimensional tolerances more than ±1.5 mm can cause misalignment, unequal load distribution, and elevated stress concentrations, according to engineering audits.

To ensure consistency between production batches, a skilled slotted channel manufacturer uses automated punching equipment and CNC-controlled roll forming. The availability of load test data is also crucial; manufacturers who offer certified load tables exhibit technical accountability and transparency.

Production Capability and Reliability

Infrastructure projects have tight deadlines. Supply chain delays are sometimes caused by firms' inability to scale their production. According to market research, during periods of strong demand, suppliers with less industrial automation are 40% more likely to fail delivery deadlines.

An established slotted channel manufacturer should demonstrate:

→High-volume production capacity

→Consistent batch-to-batch quality

→Redundancy in machinery and raw material sourcing

These factors directly influence project continuity, especially in large-scale industrial or commercial developments.

Corrosion Protection and Surface Finish

The lifespan performance of slotted channels is significantly influenced by surface treatment. About 25% of structural support system replacements in industrial and coastal settings are due to corrosion-related failures.

A reputable producer of slotted channels provides a variety of finishing choices, such as:

→Pre-galvanised (GI) coatings for indoor use

→Hot-dip galvanization in high-humidity outdoor settings

→Stainless steel remedies for exposure to chemicals or the sea

Manufacturing maturity is shown by uniform coating thickness, appropriate edge protection, and post-fabrication treatment.

Compliance, Documentation, and Certification

Regulatory compliance is a crucial consideration when selecting a slotted channel manufacturer. Reputable manufacturers integrate their processes with ISO 9001 quality management systems to ensure consistent output and continuous improvement.

The availability of load estimates, coating reports, and mill test certificates (MTCs) is crucial in regulated markets. These records lower project risk during audits and inspections in addition to supporting engineering approvals. Contractors are frequently subject to rework expenses and compliance delays when manufacturers lack verified certificates.

Personalization and Technical Assistance

Flexibility is required for modern infrastructure. Project-specific requirements might not always be satisfied by standard slotted channel profiles. Bespoke lengths, slot configurations, thickness variations, and bespoke coatings are all available from a value-driven slotted channel manufacturer.

Moreover, manufacturers with internal engineering teams offer value engineering, load optimization, and design support services that can cut material use by up to 15% without sacrificing performance.

The Perspective of Total Cost of Ownership (TCO)

By itself, price is a misleading metric. Lifecycle cost evaluations show that higher-quality slotted channel systems consistently reduce maintenance, replacement, and downtime expenses over time. Selecting a reliable slotted channel maker can save total ownership costs by 18–22% over the course of 15–20 years of operation, according to analytical calculations.

Concluding Thoughts

The choice of slotted channel manufacturer involves much more than just product pricing. System reliability and infrastructure resilience are defined by the combination of material quality, dimensional precision, production capacity, compliance, and engineering assistance. Choosing the correct manufacturer is crucial in a time when infrastructure is expected to be robust, flexible, and compliant. The appropriate slotted channel maker offers structural assurance in addition to steel.